|

|||||||||||||

This department is involved in the study to create advanced functions of material and optimize with environment by developing the smart joining and coating as finely and precisely controlled processing in nano and micrometer scales. Through the research and developments on freeform joining and coating of metals, ceramics and polymers by using stereolithography and welding systems of computer aided designing and manufacturing, we want to contribute to environment friendly and sustainable society. |

|

||||||||||||

Assoc.Prof. S. Kirihara |

|||||||||||||

|

|||||||||||||

|

|

||||||||||||

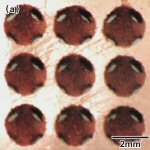

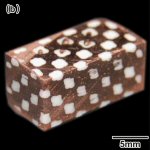

Laser Scanning Stereolithography: Photo sensitive liquid resin pastes with metals and ceramics particles dispersion were solidified continuously thorough the UV laser scanning to create solid objects. Through dewaxing and sintering, fine metals and ceramics structures will be obtained. (a) Pure Copper Photonic crystal: Metal periodic structures can diffract millimeter waves and radiate maser beams through multiple reflections. (b) Pure Copper / Alumina Thermodynamic Crystal: Geometrical arrangements of metals and ceramics phases can realize distribution controls of heat and stress flows.

|

|||||||||||||

|

|

||||||||||||

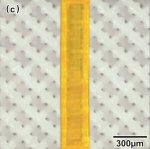

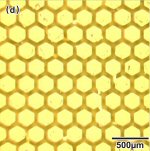

Micro Patterning Stereolithography: Micro layer patterns composed of photo sensitive resins including with nano sized metals and ceramics particles were formed exactly by UV image exposures through computer controlled digital micro-mirror devices. (c) Alumina Lattice Micro Reactor: Dielectric diffraction lattices can concentrate electromagnetic energies into a water cell to exciting biochemical molecules. (d) Titania Micro Pattern: Geometrical arrangements of dielectric polygon tablets can harmonize terahertz waves strongly for precise spectroscopic analyses of environment pollutants. |

|||||||||||||

|

|

||||||||||||

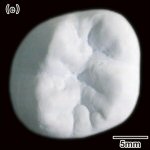

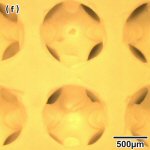

Biomimetic Freeforming: Structural data of teeth or bones in individual human bodies were captured and measured by using computer tomography or laser scanning to create biomimetic ceramics patterns made to orders through stereolithography. (e) Alumina Dental Crown: Transparent glass materials were coated on ceramic implants to increase aesthetic and mechanical properties for practical dental uses. (f) Hydroxyapatite Scaffold: Micro spherical cavities were periodically arranged in ceramic bulks to realize gradual variations in volume fractions for biocompatibility effects in human bodies. |

|||||||||||||