|

||||||||||||||

This department deals with smart coating processing

based on nanoparticle processing, which leads to

advanced manufacturing technology as well as safe, |

|

|

|

|||||||||||

Prof. M. Naito |

Assoc.Prof.

H. Abe |

Assist.Prof. T .Kozawa |

||||||||||||

|

||||||||||||||

S.A.Researcher A .Kondo |

||||||||||||||

|

||||||||||||||

.jpg) |

||||||||||||||

Formation of Multi-layered Structure on Core Particle Surface by Nanoparticle Processing in Dry Phase: SEM image of multi-layered structure on core particle surface by nanoparticle processing in dry phase (left side). Surface layer is polymer film with nanospaces, and intermediate layer is shown by EPMA mapping image (Right side). |

||||||||||||||

|

||||||||||||||

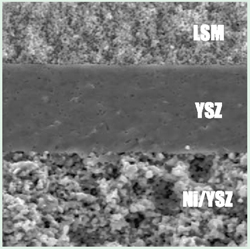

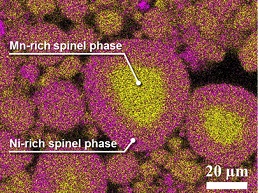

Fabrication of Both Cathode and Anode Nanostructure for SOFC by Wet Processing: LSM powder and Ni-YSZ composite powder were successfully processed. They were used for nanostructure control of both cathode and anode. |

||||||||||||||

|

||||||||||||||

Fabrication of Cathode Particle with Gradient Composition for Li Ion Battery by Dry Processing: Nanoparticles as a shell were synthesized and coated on core particles by dry powder processing. The concentration-gradient cathode particles for Li ion battery were fabricated by calcination of the core@shell particles. |

||||||||||||||