|

Technical Expert Division |

|

����w�ڍ��Ȋw�������Z�p�� |

||

Joining and Welding Research Institute Osaka University |

Tips

�@

Materials that can be coditioned are iron , copper , tungsten , carbon

and NAK.

Please choose the "Iron"setting, for Titanium, Nickel, Tin.

Please choose the "Aluminum"setting for Magnesium.

The minimum setting of thickness is up to 5mm.

Please keep in mind the following notes

in case of processing less than 5mm thickness.

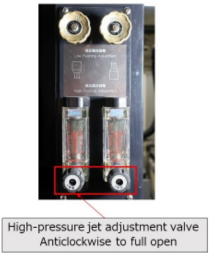

�@�@ �@Close the high-pressure jet adjustment valves.�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@ �@ �@

�@

�@

�@�@ �ALower the processing power by changing the conditions

�@�@�@�@Please contact with Technical Expert Division

for any changes inconditions.

to avoid the frequent breaking of wires

The breaking of wire occurs, when it reaches high temperature locally.

In order to enhance the cooling effect by jet flow, it is effective to keep a

distance from the wire to the material and to discharge the material sludges.As it is possible to adjust the electric discharge to the appropriate time,

to the change the servo reference voltage, or the table feed speed.

Please contact with Tecnical Expert Division.

It is possible. Please contact with Technical Expert Division.

The exclusive USB shoud be used for inputting data.

Please confirm the following,

�@�@�@Full open the high-pressure jet adjustment valve.�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@

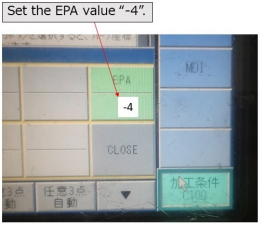

�@�ASet the EPA VAlue�@-4�@

�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@ �@

Please contact with Technical Expert Divison

This trouble needs cleaning,exchanging parts ,etc. to be solved.

Exchange the empty bobbin to the wire's.

If you need help, please contact with Technial Expert Division

(Reference) Here is a video of how to connect wires.

Please wipe away the water towels , etc.

If the water is flowing into the machine, it causes the breakdowans.

Please contact with Tecnical Expert Division immediately.

It may be that the sensor of water-leve is not working.

If the sensor rises, the water does not flow out of the tank.

Please contact with Tecnical Expert Division.

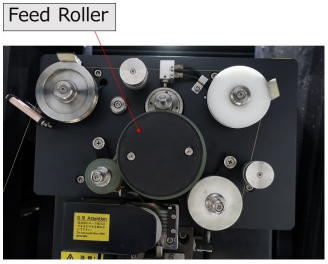

It may happen from the feed roller.

Because of loose attachment ,the reattachment shoud solve this problem.

Please contact with technical Expert Division.

�@�@�@�@�@�@�@�@�@�@�@

Do not keep processing with the tangled wire.

It can be taken off by hand, but sometimes it may need disassemble

the wire-dischraging parts.

Please contact with Technical Expert Division