Research Areas

Research Division of Materials Joining Mechanism

Dept. of Welding Mechanism

Mechanisms controlling the joint performance of structural and functional materials, which obtained by fusion welding, liquid-state/solid-state bonding, and solid-state bonding, are metallographically characterized to establish a scientific basis to produce joint materials featuring superior performance. The microstructures of the weld-deposited metal, the heat-affected zone of fusion-welded joints, and the interfacial region of solid-state bounded joint are thoroughly investigated utilizing various methods such as X-ray diffraction, electron-microscopy observation, elementary analysis, EBSP analysis, and numerical modeling and simulation. Formation processes of the microstructures and their relation to joint performance are discussed from the material scientific viewpoint.

1. Weld microstructure analyses of structural material such as steel

2. Bonding mechanism of solid-state joining of metals and ceramics, and its application to microstructural control

3. Application of welding and joining phenomena to development of advanced materials

4. Synthesis of new functional materials at welding and joining interface

5. Evaluation of the effect of microstructure on mechanical behavior of structural materials joints

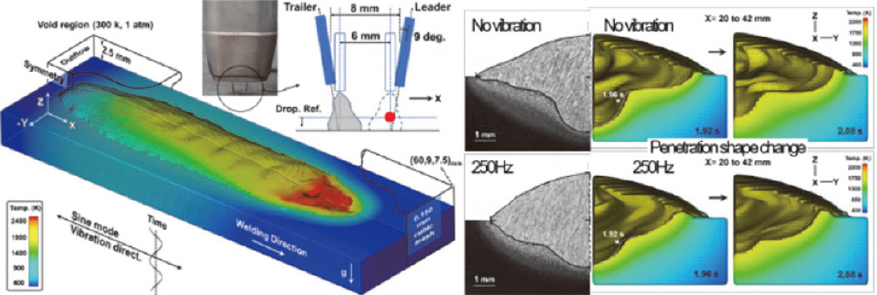

Welding-time variation of penetration shape change in the simulated vibration assisted tandem-pulsed GMAW using the Flow-3D commercial software in the presence of sine-vibration parallel to the welding direction (250 Hz) and the surface tension active elements.

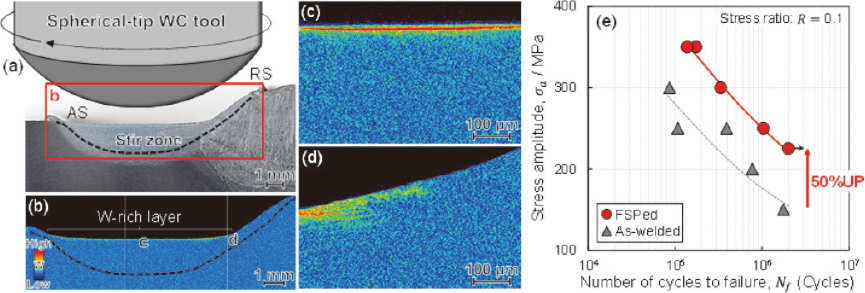

Geometry modification and W-rich layer formation for weld toe of highstrength low-alloy steel joints using friction stir processing (FSP) with spherical-tip WC tool, resulting in fatigue strength improvement.

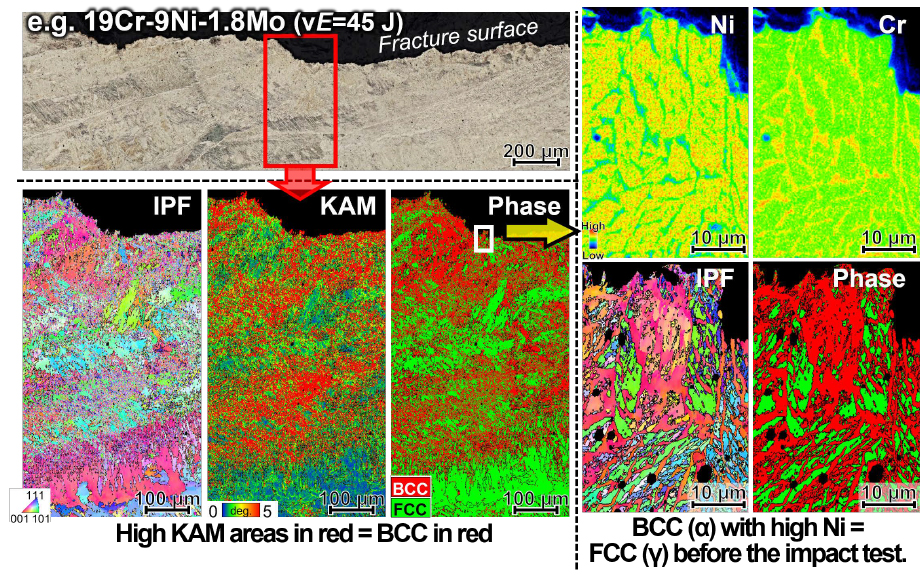

Deformation induced phase transformation from FCC to BCC occurred in an impact test of δ-ferrite-containing γ stainless steel deposited metal at liquid N2 temp., resulting in increasing ultralow-temp. toughening.

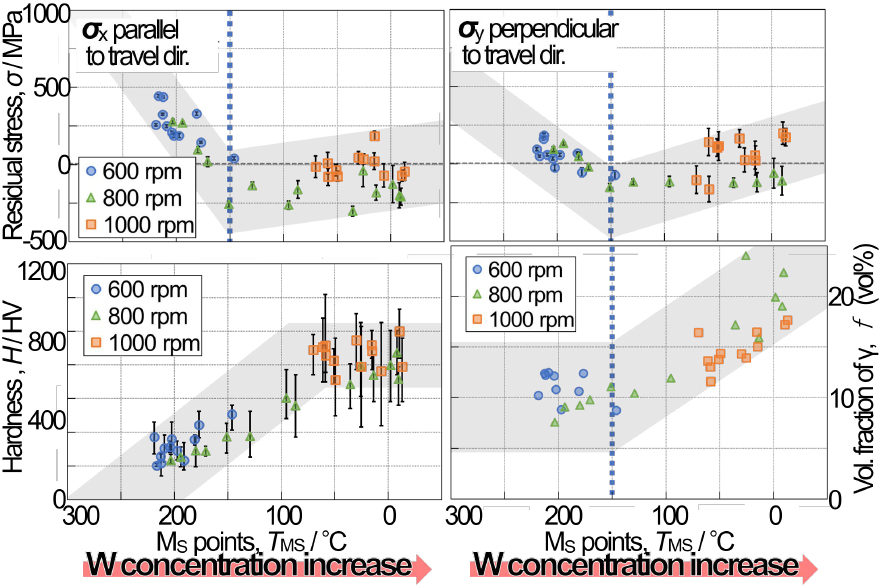

Dependence of residual stress on Ms in parallel and perpendicular directions to the FSP direction, hardness, and the volume fraction of the retained γ, in the stir zone surface FSPed at tool rotational speeds of 600, 800, and 1000 rpm.

Members

Prof.

K. ITO

Assoc. Prof.

M. TAKAHASHI

S. A. Assoc. Prof

B. ZHAO

Assist. Prof.

H. YAMAMOTO

Assist. Prof.

S.M. HONG

Research Division of Materials Joining Mechanism

Dept. of Joint Interface Structure and Formation Mechanism

In this department, based on the elucidation of various phenomena at the joint interfaces of ferrous, nonferrous, non-metal materials at both macroscop-ic and microscopic levels, the interface formation mechanisms during various joining processes are clarified to create new interface control methods.

In addition, novel welding and modification processes are developed, main-ly based on fusion welding methods and friction welding methods such as friction stir welding, rotary friction welding, and linear friction welding methods, which are the core of fundamental technologies having a great potential to produce new values. These developments are going to be used and focused simultaneously in our society in order to create a new research field and ele-vate the continuous growth of industrial competitiveness of our country.

1. Control of interface and elucidation of formation mechanism during friction welding (FSW, Friction welding, Linear friction welding)

2. Development of novel joining and modification processes

3. Elucidation of formation mechanism of weld interface and molten pool

4. Analysis of joint interface structure

5. Control of solid-liquid interface formation

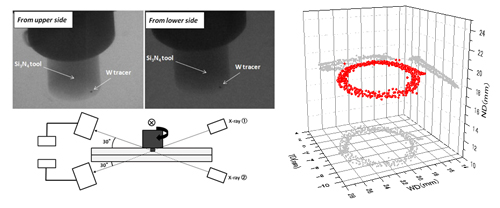

Three-dimensional visualization of the material fl ow using a W tracer during the FSW.

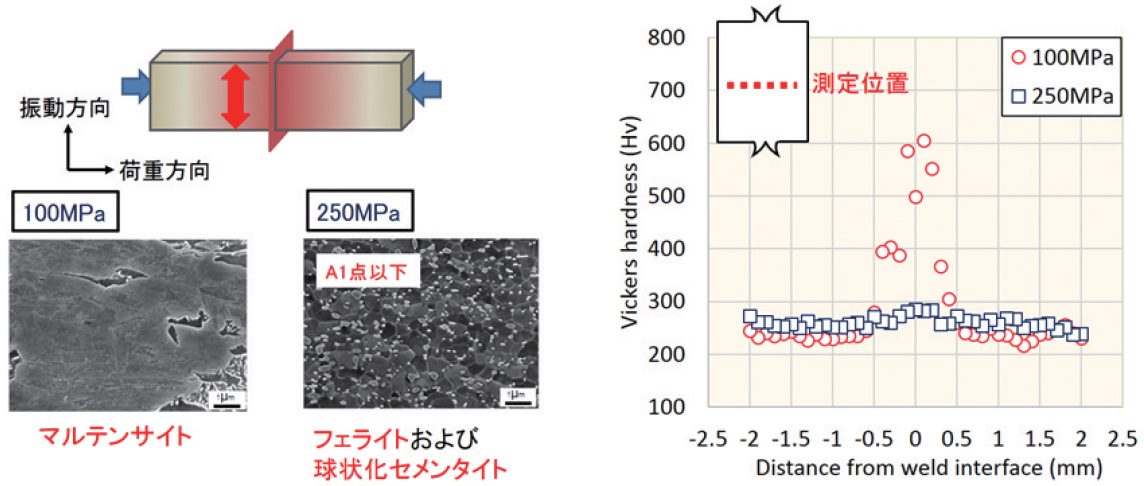

SEM microstructures and Vickers hardness along the central axis of LFWed joints.

Members

Prof.

H. FUJII

Assist. Prof.

T. YAMASHITA

Assist. Prof.

A. SHARMA

S. A. Prof.

K. USHIODA

S. A. Assoc. Prof.

Y. MORISADA

S. A. Assoc. Prof

Y. AOKI

S. A. Researcher

M. KAMAI

Research Division of Materials Joining Mechanism

Dept. of Composite Materials Processing

From a viewpoint of the energy saving and environmental problem solutions, the research fields of this department focus on both of the effective reuse of resources and energy including renewable ones and reduction of life hazardous materials and air pollutions. In particular, by controlling the interfacial mechanics and high-performance of materials, atomic/nano-scale composite materials and processing designs for the environmentally benign are established, and applied to innovative industrial development.

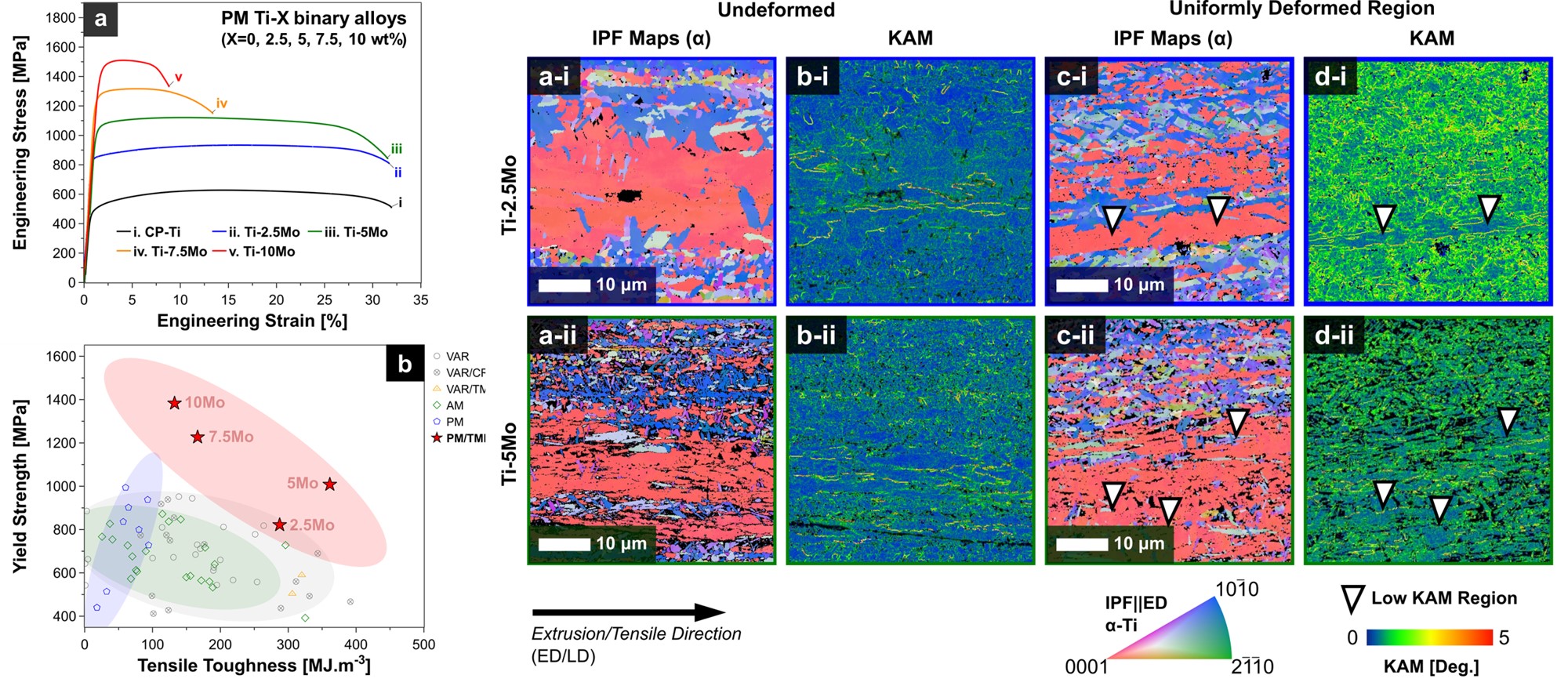

1. Titanium materials with high-strength and ductility via atomic-scale microstructure optimization by first principle calculation

2. Nano-carbon materials reinforced metal matrix composites through interfacial mechanics

3. Surface modifi cation by 3D-nano structuring and application to novel biomaterials

4. Direct bonding of plastic materials to metals by molecular structure control

5. Nano-porous structured silica materials originated from rice husks

6. SKPFM analysis on local galvanic corrosion behavior of Mg alloys and corrosion resistance improved by surface modification

Microstructure development and strengthening behaviour in hot-extruded Ti-Mo alloys with exceptional strength-ductility balance

Jeff Huang, et al., Journal of Alloys and Compounds, 1010 (2025) 177195.

Members

Prof.

K. KONDOH

Prof.

J. UMEDA

Assoc. Prof.

S. KARIYA

Research Overview

Research Division of Materials Joining Process

Research Division of Materials Joining Mechanism

Research Division of Materials Joining Assessment

Research Center for Additive Joining Application (RAJA)

Strategy Office for Promotion of Inter-Institute Collaborations

Joint Interface Microstructure Characterization Room

Global D&I Promotion Office

New Normal Manufacturing Consortium Office

Research Alliance Laboratories

Joint Research Chair

International and Industry-academia Joint Research Center