Research Areas

Research Alliance Laboratories

DAIHEN Welding and Joining Research Alliance Laboratories

DAIHEN Welding and Joining Research Alliance Laboratories was established in Joining and Welding Research Institute, Osaka University since April 2019 aiming at technological development for innovative high performance and high efficiency in welding and joining fields.

Innovative R&D of the welding and joining technologies that brings about a shift in manufacturing is being promoted by combining the welding and device development technologies of DAIHEN corporation with the world class academic research of Joining and Welding Research Institute, Osaka University and education and research of Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University.

Targets

1) R&D that aims at improving the performance and expanding the application range of high quality and high efficiency welding process, that brought by essential understanding of arc physics and elucidation of joining mechanism from welding metallurgical point of view and prediction / evaluation of reliability.

2) R&D that aims at world’s top level novel joining technologies and high performance of welding process applying visualization technology, that brought by fusing the knowledge from the global academic research at Osaka University and the welding equipment and process control technology by DAIHEN corporation.

3) Raising world-class engineers and researchers by promoting students and young engineers to actively participate in the projects.

1. Research and development of cold spot joining process

2. Research and development of welding process monitoring and its ap-plied technology by visualization

3. Research and development on joining and separation of dissimilar materials

4. Research and development of super durable welding torch

(1) Cold Spot Joining System

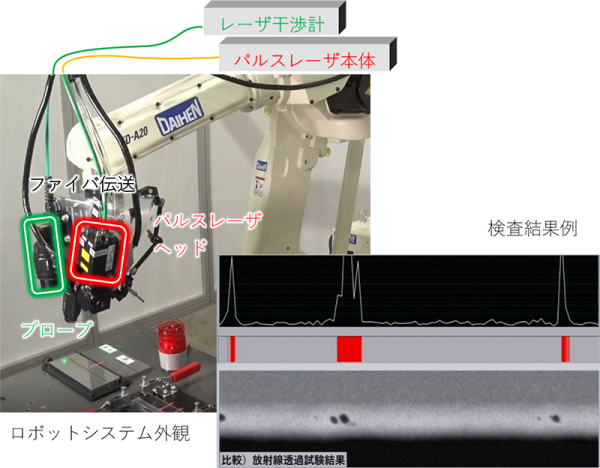

(2) Robotic system using Laser Ultrasonic Technic for non contact inspection.

(3) Laser arc hybrid dissimilar material joining system

(4) Development of durable torch

Members

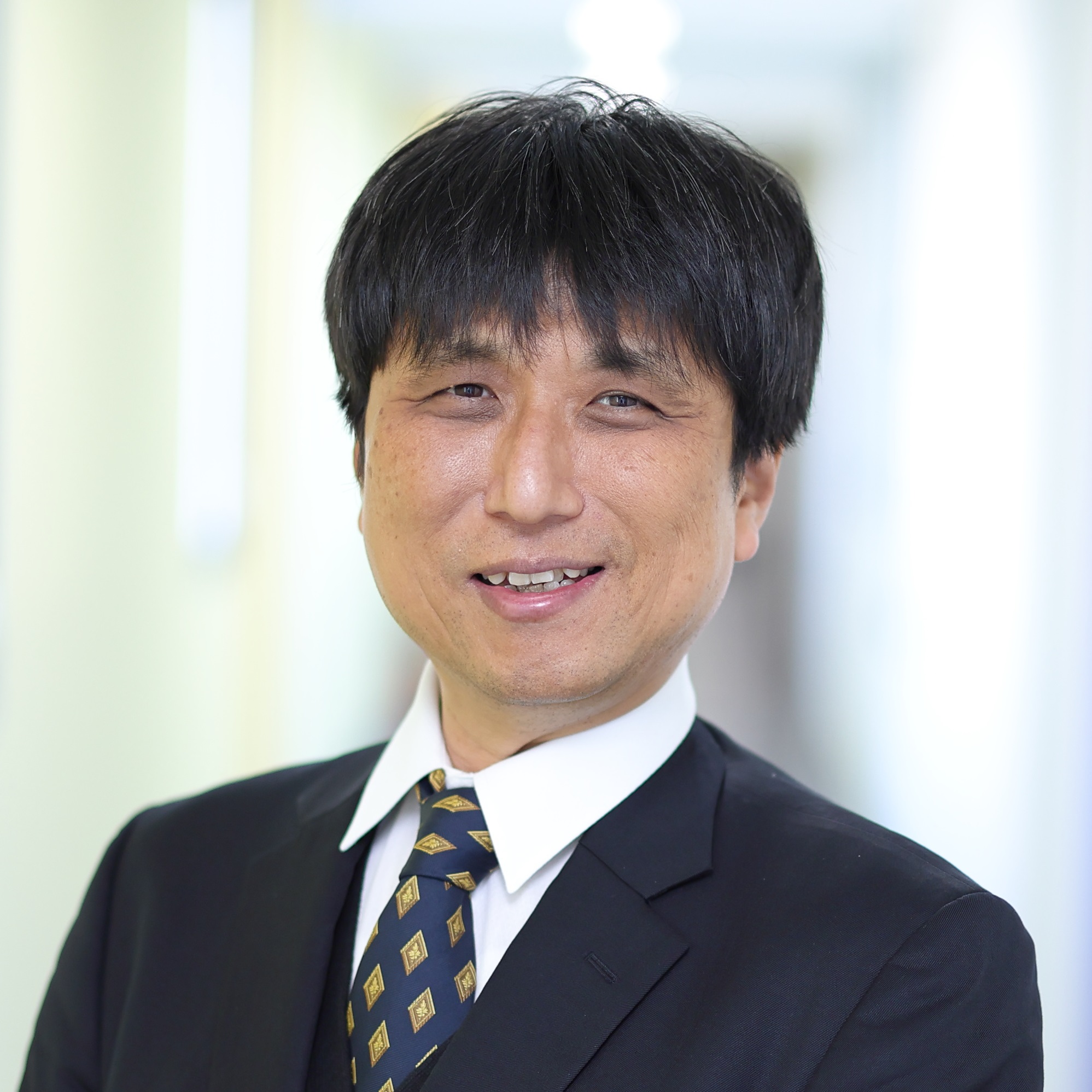

Director Prof.

H. FUJII

Vice Director G. Prof.

T. ERA

S. A. Prof.

S. ASAI

G. Assoc. Prof.

K. KADOTA

S. A. Assist. Prof.

Y. TAKEI

Research Alliance Laboratories

Nippon Steel Future Manufacturing Research Alliance Laboratories

Nippon Steel Future Manufacturing Research Alliance Laboratories was launched on April 2021 in JWRI, with the aim of developing innovative welding and joining technologies that will open up the future of manufacturing.

For realizing infinite potential of steel, R&D activities are being promoted by bringing together the world-leading research on welding and joining of Osaka University and material technology of Nippon Steel Corporation.

1. R&D on welding and joining processes contributing to application of advanced-steel

2. R&D on welding and joining metallurgy which contribute to improving reliability of welded/joined steel structures.

3. Raising researchers, who lead welding and joining technologies in future, through participation of students and young researchers in R&D.

Examples of research

1. Evaluating applicability of joining process to advanced-steel

2. Elucidation and visualization of welding metallurgy

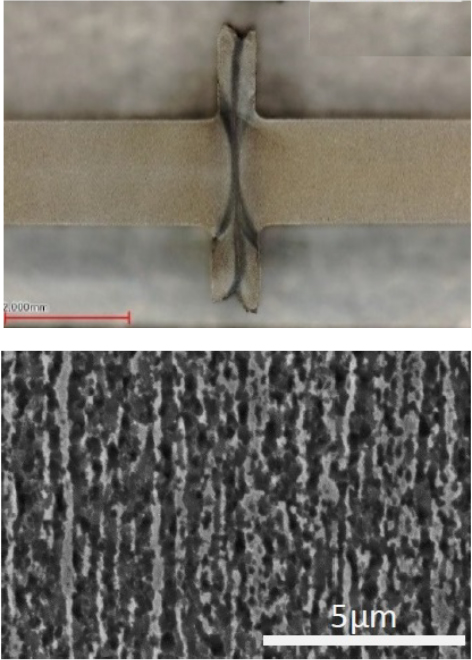

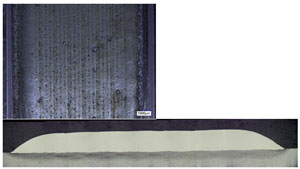

Macro and microstructures of liner friction welded joint of ultra high strength steel

(Photo : Provided by Research division of material joining mechanism)

Solidification cracking in laser welded steel plates

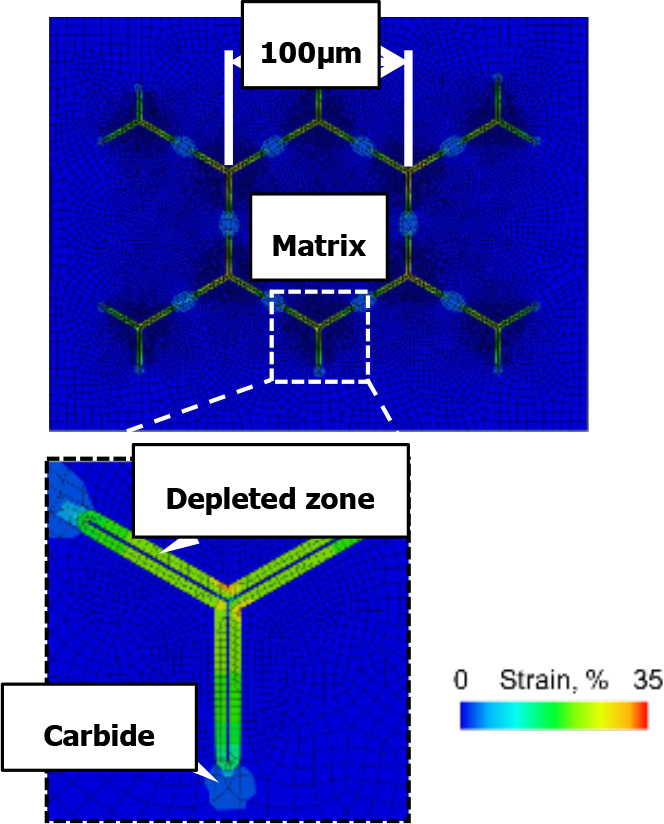

An Example of strain analysis for microstructural changes of welds due to aging

Members

Director Prof.

H. FUJII

G. Prof.

H. NISHIBATA

S. A. Assist. Prof.

K. JOTOKU

Research Alliance Laboratories

Honda-Osaka Univ. Joining Technology Monozukuri Research Alliance Laboratories

By 2050, Honda aims to realize a recycling-oriented society with “zero environmental impact” not only for products but also for the entire life cycle, including corporate activities. “Honda-Osaka Univ. Joining Technology Monozukuri Research Alliance Laboratories” has been established in Joining and Welding Research Institute, Osaka University in March 2024 to accelerate research and development that will bring innovation to mobility manufacturing. By fusing Osaka University's state-of-the-art joining technology with Honda's unique and original body technology, we will create exciting futures of mobility by realizing new joining technologies.

Targets

1) Development of joining technology aimed at product and factory evolution for achieving carbon neutrality by combining Osaka University's state-of-the-art joining science knowledge with Honda's production processes, core technology development capabilities, and ability to introduce on vehicle bodies and mass production.

2) The idea of a basic process that leads to easy disassembly and material separation technology, and research on the necessary technology to realize the process in order to realize resource circulation (closed recycling system).

3) Cultivation of strong researchers and engineers who can create an exciting future through activities where experts and students/young researchers respect each other's diverse ideas and opinions and can grow by thinking through the purpose and essence of each other.

1. Development of solid phase resistance spot joining technology and quality evaluation technology based on easy disassembly/material separation theory

2. Research on basic processes and necessary technologies that lead to easy disassembly/material separation technology

3. Further academic exploration and expansion of Honda's joining technology

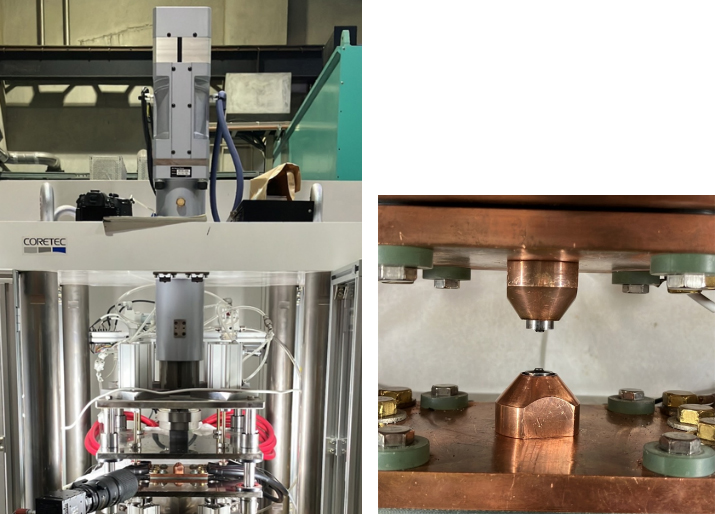

(a) Solid phase resistance spot joining experiment machine

Reference : 20170727_civic-sedan_hatchback_p18.pdf (honda.co.jp) (March 12th 2024)

(b) Inner frame body structure and roof blaze joining technology

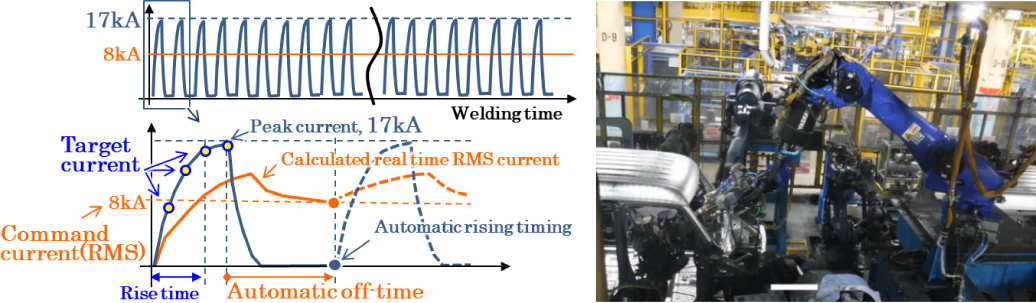

Reference : 「パルス電流の波形制御と休止時間自動制御による高板厚比三枚重ねスポット溶接技術の開発」溶接学会全国大会講演概要集, 第114集 (2024).

(d) CDC new spot welding technology

Members

Director Prof.

H. FUJII

Vice Director Prof.

R. IKEDA

Vice Director G. Prof.

S. WATANABE

G. Researcher

T. MURAKAWA

S. A. Researcher

H. TOYODA

G. Researcher

M. KAMIKURA

G. Researcher

H. SAITO

G. Researcher

H. KOBAYASHI

Joint Research Chair

Osaka Fuji Advanced Functional Processing Joint Research Chair

This research chair aims to develop advanced functional processing technics by combining laser processing technology and materials knowledge in JWRI and advanced functional manufacturing technologies of Osaka Fuji Corporation. The main purpose is to develop the surface functioning of various materials by laser cladding method, low weldability materials. Finally, these fruits are applied to the next generation of manufacturing technology fo various industrial fields.

1. Development of highly functional surface by laser cladding

2. Development of functional surfaces of small or thin parts

3. Development of hybrid technology of laser and conventional surfacing technologies

4. Fundamental research of laser additive manufacturing technology

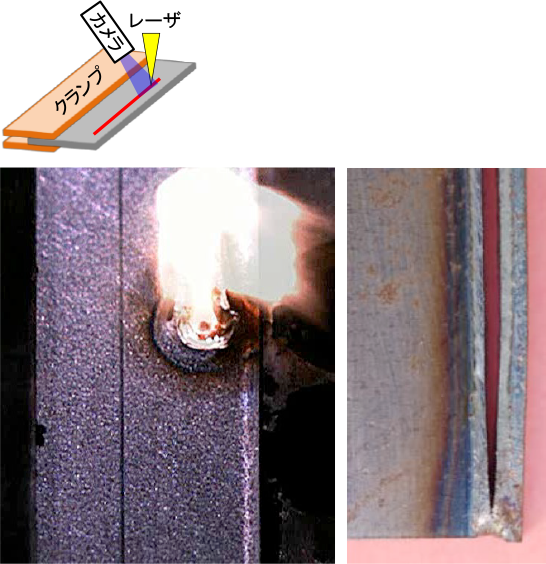

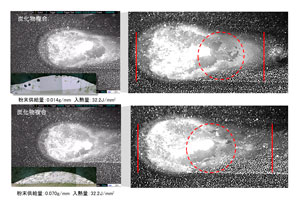

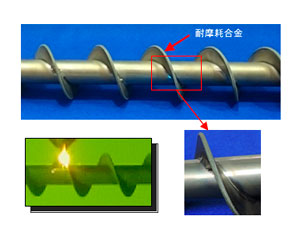

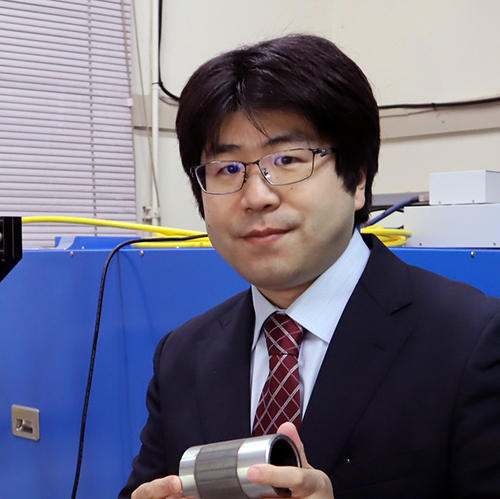

Dynamic observation of molten pool behavior for analysis of blow halls formation using high-speed camera

Example of laser cladding on edge of screw

Experimental apparatus for laser cladding

Members

Prof.

M. TSUKAMOTO

Assoc. Prof.

Y. SATO

S. A. Assist. Prof.

Y. HAYASHI

S. A. Assist. Prof.

M. MIZUTANI

S. A. Researcher

K. IKEDA

G. Researcher

K. MORIMOTO

G. Researcher

Y. TATSUMI

Research Overview

Research Division of Materials Joining Process

Research Division of Materials Joining Mechanism

Research Division of Materials Joining Assessment

Research Center for Additive Joining Application (RAJA)

Strategy Office for Promotion of Inter-Institute Collaborations

Joint Interface Microstructure Characterization Room

Global D&I Promotion Office

New Normal Manufacturing Consortium Office

Research Alliance Laboratories

Joint Research Chair

International and Industry-academia Joint Research Center