Research Areas

Research Division of Materials Joining Assessment

Dept. of Joining Mechanics and Analyses

The department of joining mechanics and analyses is dedicated to solve structural manufacturing and application problems, in which various phenomena, i.e. heat sources, materials, processes, and mechanics, coupled in the welding, joining and additive manufacturing, are revealed by numerical simulation based on mathematical modeling and Artificial Intelligence. With the aid of AI enhanced research software JWRIAN and advanced measuring technology, safety and reliability of various structures manufactured by joining/welding are evaluated.

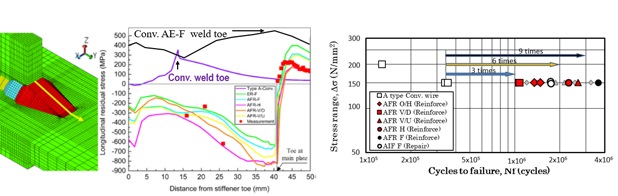

1. Thermal-mechanical analysis of joining/welding stress/strain and fatigue life

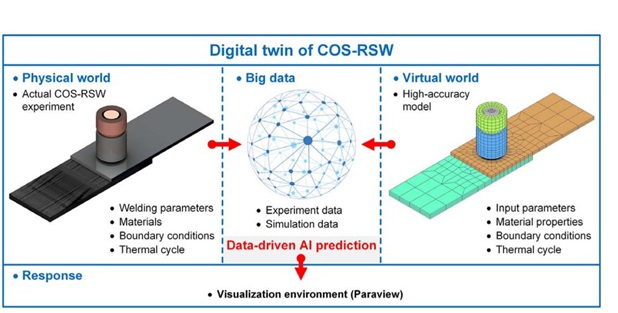

2. Digital twin for Metals/CFRTP welding process

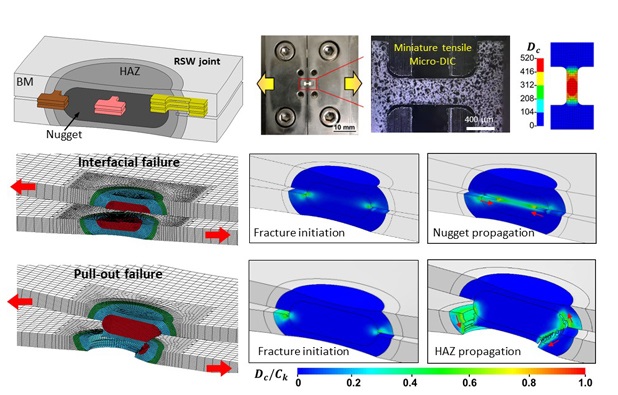

3. Analysis and measurement of stress/strain/strength of dissimilar welded joints

4. Thermal-mechanical analysis of additive manufacturing process and stress/strain/strength

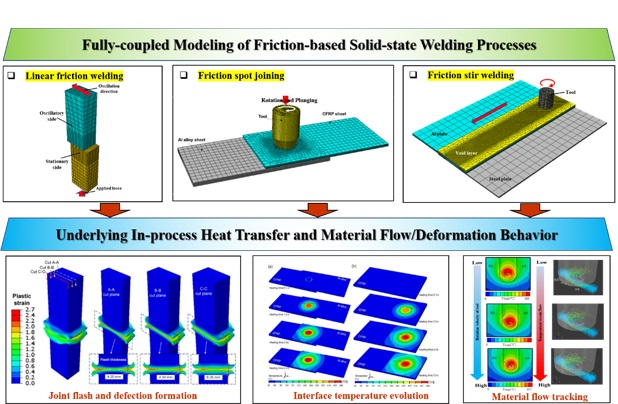

5. Thermal-mechanics and materials fl ow analysis of friction-based solid-state welding processes

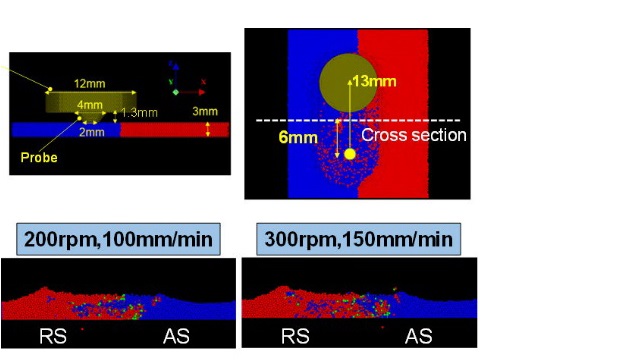

6. Particle method for dissimilar materials flow analysis in friction stir welding

Research Concept of Joining Mechanics and Analyses

(a)IGA for optimal shape design of welded joint in structures

(b)Digital twin for Metals/CFR TP resistance spot welding

(c)Miniature tests of weld and HAZ for strength analysis

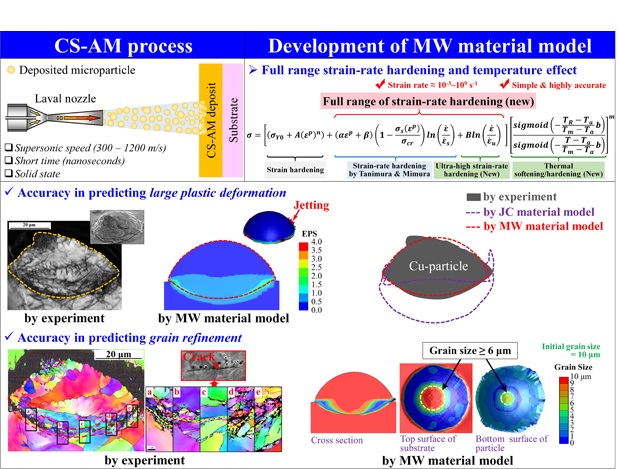

(d)M-W model for thermal-mechanical analysis of AM process

(e)Euler-Lagrange Coupling for various friction stir welding

(f)Additive manufacturing induced residual stress

Members

Prof.

N. MA

S. A. Prof.

K. NAKAO

S. A. Assist. Prof.

W. Huang

S. A. Researcher

K. NARASAKI

Research Division of Materials Joining Assessment

Dept. of Joining Design and Structuring

In this research division, the structural design and fabrication processes are considered on the following two aspects: the "through-process" and "trans-scale." The concept of "through-process" considers the time axis throughout the life cycle, from the design and construction process, such as welding and joining, to testing, service, repair, reinforcement, and maintenance. The concept of "trans-scale" considers spatial axes ranging from micro to macro, such as the microstructure of materials of welds, welding and joining components, and structures.

We research the evaluation of the performance and reliability of various structures at each of these stages and scales. In particular, the effects of thermal processing, represented by residual stresses and deformations, on the performance of welded and joined components and structures will be clarified from both microscopic and macroscopic perspectives. We will also develop a detailed and intelligent evaluation method based on these findings. Our goal is to establish design engineering that contributes to the advancement of structuring processes such as welding and joining.

1. Development of evaluation methods for strength properties and reliability of structural members, welds and joints

2. Development of performance evaluation technique for welded structures in consideration of residual stress

3. Development of manufacturing process simulation technology for design applications

4. Development of damage evaluation method considering microscopic plastic deformation behavior of materials and welds

5. Evaluation of cracking characteristics considering heterogeneity of structural materials and weld

Simulation technique for joint characteristics considering weld residual stress and effects of fabrication and loading

Fatigue performance prediction method consider-ing joint characteristics

Members

Prof.

Y. MIKAMI

Assist Prof.

H. ZHOU

Research Division of Materials Joining Assessment

Dept. of Joining Metallurgical Evaluation

The welding and joining technology is required to achieve high-performance properties of the materials, which is essential in manufacturing industrial products and structures using high-performance materials. There is a demand for innovative welding and joining technologies that can be applied to similar and dissimilar materials.

The Department of Joining Metallurgical Evaluation researches to improve the properties and reliability of weld joints when welding similar or dissimilar materials using high-performance materials, focusing on welding processes such as fusion welding and solid-state joining. Our department elucidates the governing mechanisms in the formation process of welds and welding microstructures, the mechanisms of the occurrence of welding defects, and research to develop new welding technologies that can control the properties of weld joints.

1. Development of resistance spot welding technology for advanced sheet materials

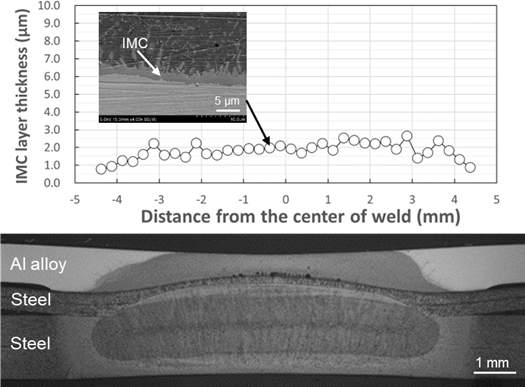

2. Analysis of weld interface structure of dissimilar welded joints

3. Development of tailored dismantling technique of welds and joints

4. Improvement and prediction of weld cracking susceptibility by microstructural control

5. Development of evaluation method for solidification/transformation behavior and hot cracking susceptibility during welding and additive manufacturing

6. Elucidation of influential factors of corrosion resistance of welds

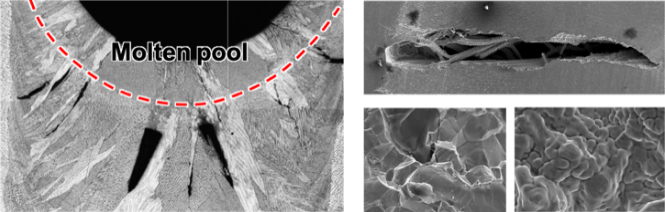

Evaluation and analysis of hot cracking susceptibility test

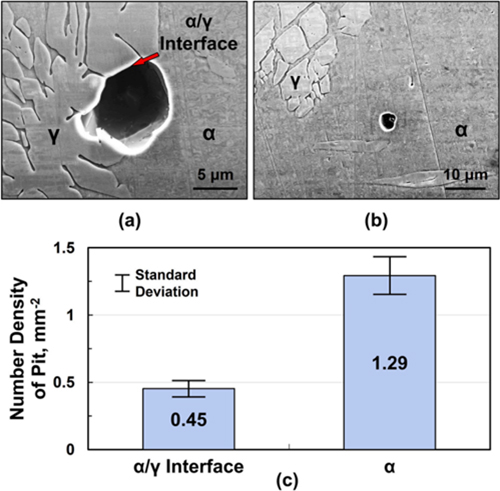

Observation of pitting initiation in heat-affected zone by FESEM

(a)α/γInterface and (b)α-ferrite, (c)Location of pitting initiation

Cross-sectional photo and IMC thickness distribution of weld interface of resistance spot weld of aluminum alloy sheet to high-strength steel sheet

Members

Prof.

R. IKEDA

Assoc. Prof.

K. KADOI

Research Overview

Research Division of Materials Joining Process

Research Division of Materials Joining Mechanism

Research Division of Materials Joining Assessment

Research Center for Additive Joining Application (RAJA)

Strategy Office for Promotion of Inter-Institute Collaborations

Joint Interface Microstructure Characterization Room

Global D&I Promotion Office

New Normal Manufacturing Consortium Office

Research Alliance Laboratories

Joint Research Chair

International and Industry-academia Joint Research Center